Direct Thermal Labels

Direct thermal labels offer simplicity, affordability, and reliable performance for businesses of all sizes. Our American-made labels and tags serve many industries, including automotive, distribution, logistics, healthcare, and manufacturing, providing a straightforward solution for producing clear, readable prints without ink, toner, or ribbons. Our factory-direct pricing and vertical integration allow us to deliver premium quality at competitive prices with fast shipping times.

Need compliance labels? Our American-made AIAG labels meet industry standards.

Core

Format

Label Size

Material

Applications

Printer Compatibility

What Are Direct Thermal Labels?

The technology behind direct thermal printers relies on heat-activated chemical coatings applied to label surfaces. When the printhead applies heat to specific areas, the coating turns dark, creating text, barcodes, or graphics without requiring ink or toner.

Users prefer direct thermal for many practical reasons. The print quality remains sharp and readable without the ongoing expense of ribbons or ink. The best printers run at high speeds, producing hundreds of finished labels every minute, perfect for operations with high-volume needs.

Direct thermal labels are not ideal when exposed to sunlight, heat sources, or chemical vapors for extended periods of time. Most customers find direct thermal ideal for indoor applications where labels will be used within a reasonable timeframe.

Want durable identification? Our thermal transfer labels withstand chemicals, abrasion, and extreme temperatures.

Choosing the Right Direct Thermal Labels

Material and Adhesive Options

Direct thermal labels come in several material types to match your application needs. Each material offers different benefits for specific environments:

Economical option for short-term indoor applications with good print quality and readability. Best for shipping labels, inventory, and applications with limited environmental exposure.

Non-adhesive direct thermal tag stock for identification where adhesives aren’t suitable. Good for event admission, temporary price tags, the KanBan system, and indoor inventory control tickets.

Our proprietary silver direct thermal material maintains readability in direct sunlight and harsh environments where standard materials fail. Excellent for outdoor applications, wiring diagrams, rating plates, electronic labels, window/glass applications, chemical drums, and durable tote tracking.

Durable synthetic material with a matte finish. Provides moderate resistance to moisture. Ideal for indoor applications such as inventory and port labeling.

Label Sizes and Dimensions

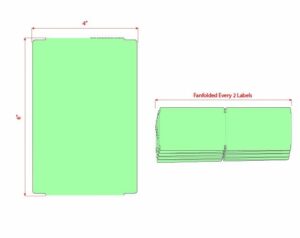

Direct thermal labels are manufactured in numerous sizes and dimensions. The most frequently used size is a 4”x 6”, although sizes can range from smaller to much larger. The quantity per label roll varies substantially based on label size, from a few hundred labels per roll to over 5,000 labels.

When selecting appropriate label sizes and dimensions, consider practical factors like the amount of information to print, application surface size, orientation preferences (landscape vs. portrait), and similar requirements. Precise label measurements help ensure compatibility with your direct thermal printer and maximize label space usage.

Get Started Today

Start your journey with BarcodeLabels.com today and enjoy a smooth, hassle-free experience distributing our premium PolyMatte labels. Our streamlined onboarding process makes it easy to begin your distribution partnership with minimal paperwork and maximum support. In just a few simple steps, you can gain access to our complete PolyMatte label catalog, exclusive distributor pricing structures, and dedicated resources designed to set you up for success.

- Bulk Order Pricing

- A Comprehensive Range of Stock Items

- Personalized Account and Dedicated Team

- Superior Shipping

- Customization

- Verticle Integration

FAQs

What are direct thermal labels?

Direct thermal labels are specialty printing materials with heat-sensitive coatings that darken when activated by the printhead in a thermal printer, requiring no ribbon, ink, or toner to produce printed images.

How long do direct thermal labels last?

The lifespan of direct thermal labels typically ranges from 6-12 months in normal indoor conditions, though exposure to heat, sunlight, and chemicals can significantly reduce their readability over time.

What are the ideal environmental conditions for storing direct thermal labels?

Store your direct thermal materials in a controlled environment with temperatures between 50-90°F and humidity levels at 40-60%. Keep them away from direct sunlight and UV light, which can break down the thermal coating over time. These conditions prevent the thermal coating from activating prematurely and protect both the paper substrate and adhesive from damage.

How should I physically handle and store direct thermal label rolls?

Handle thermal label rolls carefully by avoiding stacking heavy items on top of them, as this can cause adhesive transfer between layers and damage the roll structure. Store rolls upright when possible or use proper shelving. Keep materials in sealed containers or covered storage areas to protect them from dust, which can stick to the adhesive surface and cause printer feeding problems.

Should I rotate my direct thermal label inventory?

You should rotate your direct thermal label inventory using a first-in, first-out system to ensure you’re using the oldest inventory first. This keeps you within the optimal performance window and prevents waste from expired materials.