QR Labels

Industrial-Grade Labels Built for Business

QR code labels deliver serious data storage capacity while accommodating harsh industrial conditions. Our American-made labels can handle any QR and barcode need, from asset tracking to inventory management. Using our best materials, whether synthetic or paper, barcode and QR labels are made with the customer in mind.

Core

Format

Label Size

Material

Applications

Printer Compatibility

Traditional Barcode vs. QR Code Labels

Data storage capacity separates QR code labels from traditional linear barcodes while maintaining the fast scanning speeds your team needs. Where standard barcodes max out at 20-25 characters, QR codes hold up to 4,000 characters, including serial numbers, maintenance records, and detailed specifications.

Barcodelabels.com’s thermal transfer products allow customers to produce high-contrast, sharp-edged QR codes in-house that scan reliably with handheld scanners and smartphones. Our polyester blank labels and tags for QR codes maintain their scanning performance even after exposure to moisture, chemicals, and the rough handling that destroys paper alternatives:

Industries We Serve with QR Labels

Manufacturing, healthcare, and warehouse operations depend on labels where durability and data capacity matter. From automotive plants to distribution facilities, QR labels handle applications where traditional options fall short:

Manufacturing

Asset labels and tags with QR codes store maintenance histories, installation dates, and warranty information. Our PolyMatte labels stick to machinery permanently while scanning reliably through years of industrial use, compatible with AIAG, Plex, Kanban, and other tracking platforms.

Warehouse and Distribution

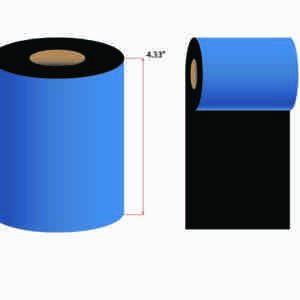

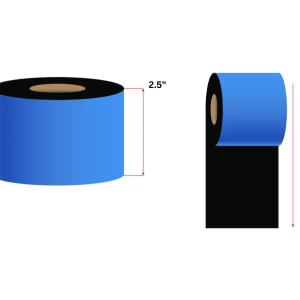

QR code and barcode labels handle inventory management by storing detailed product information, lot numbers, and shipping data in scannable format. These labels work with your existing Zebra, Intermec, Datamax, TSC, Sato, and Cab printers using our BMR Full Resin or Black Max Wax ribbons.

Chemical Environments

When standard labels dissolve or peel off, our polyester QR code labels with aggressive tire adhesive maintain their grip. These durable labels handle solvent exposure, temperature extremes, and chemical cleaning without compromising code readability.

QR Label Options, Printer Compatibility & Ribbons

Industrial QR tags need three things to perform: crisp thermal transfer printing for scanner reliability, durable face materials that resist environmental damage, and aggressive adhesives that stay put on these target surfaces. We offer options for all these needs. Our QR code labels work with major industrial printer brands, including Zebra, Intermec, Datamax, TSC, Sato, and Cab models. Ribbon selection impacts print quality and durability:

Materials

BS5609 certified material with matte topcoat for sharp laser printing; conforms to curved surfaces and resists chemicals, moisture, tears, and UV exposure.

Cost-effective solutions for QR codes, barcodes, and general labeling in controlled environments.

Order QR Code Labels Direct from the Manufacturer

We manufacture QR code labels at our US facility using materials that outperform imported alternatives while delivering factory-direct pricing. Our vertically integrated process eliminates middleman markups, giving you professional-grade QR code labels at prices that make sense for your budget. Email [email protected], or fill out our contact form to discuss your QR labeling needs.

FAQs

QR code longevity depends entirely on the label material and printing method used to create it. Thermal transfer printing on synthetic materials like polyester or polypropylene can maintain QR code readability for years even when exposed to harsh industrial conditions, moisture, and chemical exposure.

Traditional barcodes store data in horizontal lines and can hold limited information like product numbers, while QR codes use a square pattern of dots that can store significantly more data including URLs, contact information, and text. QR codes can be scanned from any angle using smartphones, whereas barcodes typically require dedicated scanners and must be read horizontally for optimal performance.